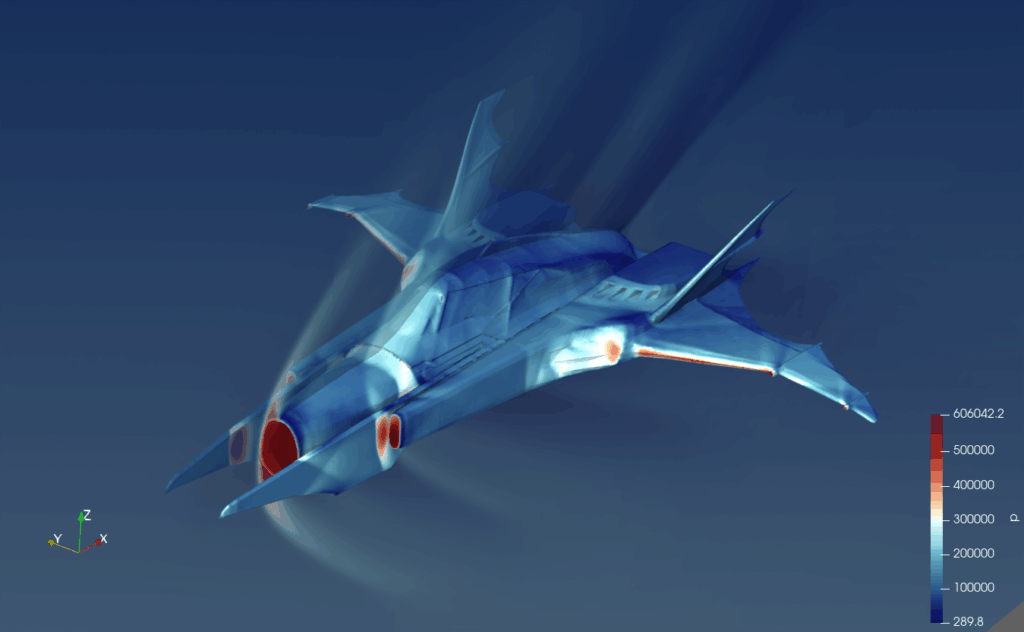

What is Computational Fluid Dynamics (CFD)?

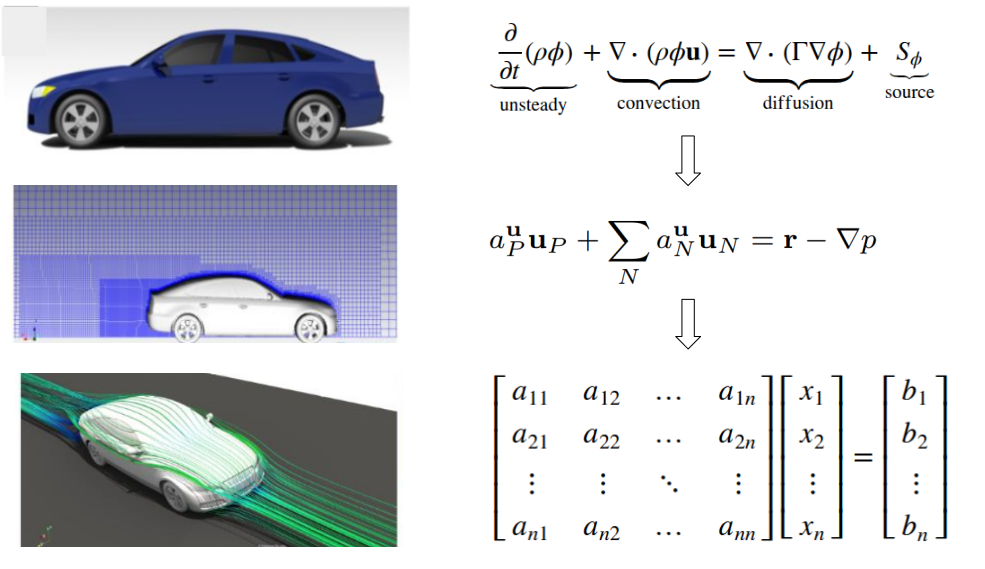

CFD is an abbreviation for Computational Fluid Dynamics, and is a discipline that uses computers to calculate the governing equations that describe the motion of a fluid and predict its physical characteristics according to temporal and spatial changes.

The governing equations consist of the Navier-Stokes equations for the conservation of momentum, the continuity equation for the conservation of mass, and the energy equation for the conservation of energy. These equations consist of nonlinear partial differential equations, making exact solutions difficult to obtain. Therefore, numerical analysis techniques are used to obtain approximate solutions.

Typically, the Finite Volume Method (FVM) discretization technique is used to convert partial differential equations into algebraic equations, and then the solution is obtained through matrix calculation of the algebraic system of equations. Space is divided into small pieces called cell, values at the cell centers are calculated, and values at faces and points are found through interpolation.

Turbulent flow problems

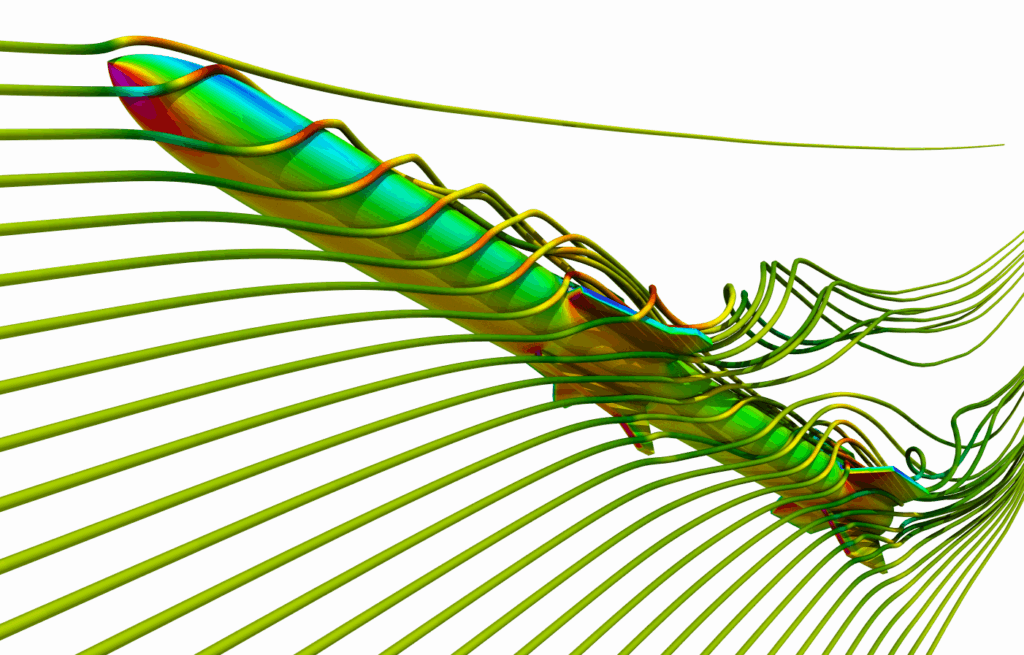

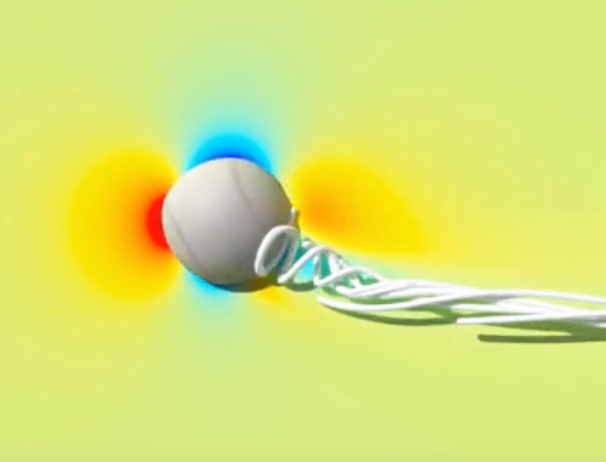

When velocity is high and viscosity is low, turbulent flow occurs, characterized by significant velocity fluctuations. Most engineering problems involve turbulent flow, and turbulence significantly affects physical properties such as flow velocity, pressure, heat transfer, and mass transfer. Capturing all turbulent components across various scales requires enormous computational costs, so modeling methods are used.

The most commonly used method is to model the influence of turbulent components on the main flow using time-averaged turbulent viscosity. The Reynolds-Averaged Navier-Stokes (RANS) equations, which are time-averaged versions of the Navier-Stokes equations, are used, and separate turbulent transport equations are calculated. The overall governing equations consist of one continuity equation, one energy equation, three momentum equations in the x, y, and z directions, and one to six additional turbulent transport equations depending on the turbulence model.

Applications and Cases of CFD

Traditional applications

Traditional applications of CFD include aerospace, shipbuilding, energy, the environment, construction, and civil engineering, all of which rely on fluid behavior to determine the performance of products or systems. Key applications include:

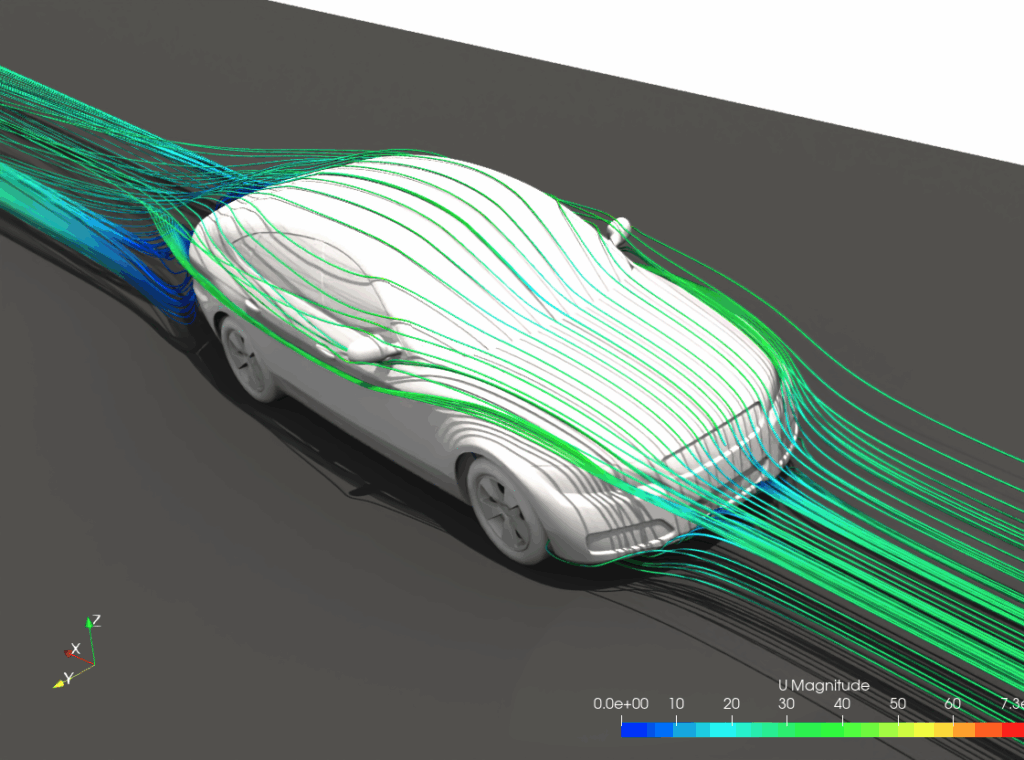

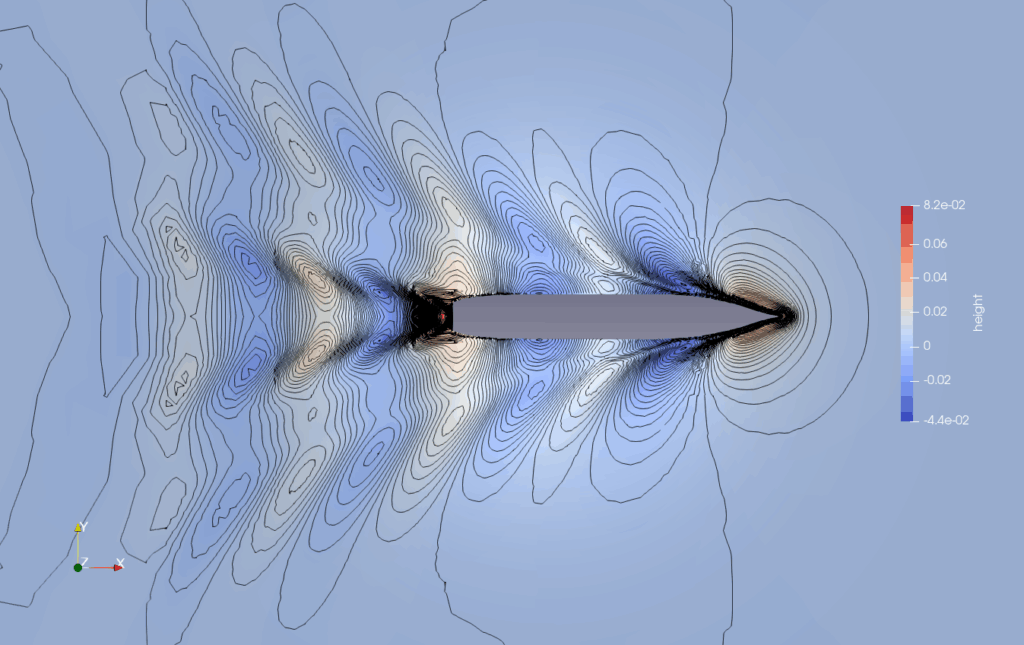

- Moving objects where fluid force is important, such as aircraft, vehicles, ships, submarines, missiles, and torpedoes

- Fields where fluid mixing and chemical reactions are important, such as thermal power generation and environmental facilities

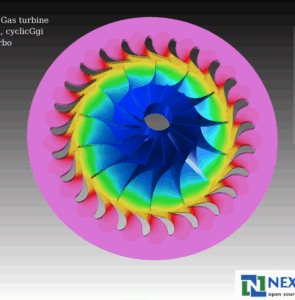

- Fluid machines that operate by fluid force, such as compressors, turbines, fans, and pumps

- Structures that are significantly affected by wind, such as buildings and bridges

- Ventilation problems inside buildings, transport vehicles, clean rooms, etc.

Expansion of fields of application

As product performance improves across various industries, the need for thermal fluid solutions grows. These solutions are being used to address issues such as heat generation resulting from the miniaturization of electronic products, ventilation/cooling systems in data centers, and efficiency enhancements in chemical plants.

Recently, with the growing importance of environmental and safety issues, the field has expanded to include alternative energy sources like wind power, batteries, and fuel cells, disaster management such as fires, typhoons, and floods, and urban wind conditions. Beyond industrial applications, medical and leisure applications are also increasing, including vascular flow, sports cars, drones, bicycles, motorcycles, swimming, and baseball. See more cases

Characteristics and difficulties of CFD

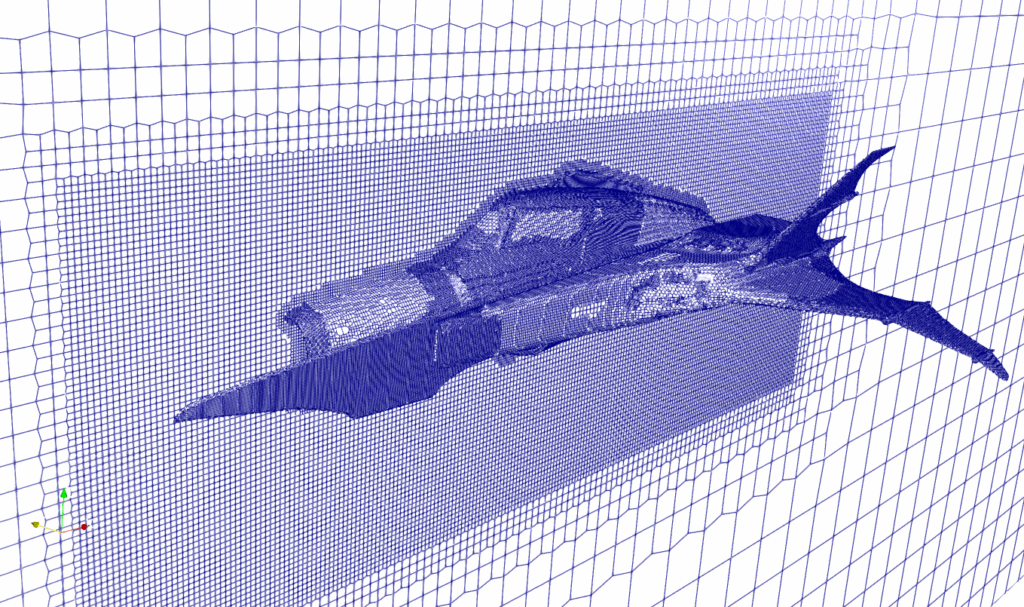

- High-resolution mesh is required: Fluid motion varies over many scales, and very small, high-resolution mesh are required to predict fine-scale changes.

- High-performance HPC required: High-resolution mesh require a very large number of cells, which leads to significantly longer computation times. High-performance HPC is required to obtain results within a time frame usable in the product design process.

- Because many problems involve the complex interaction of various physical phenomena, obtaining good results requires knowledge in various fields, including fluid mechanics, heat transfer, multiphase flow, phase change, chemical reactions, noise, and electromagnetic fields.

- Because the phenomenon itself is invisible and difficult to measure, it is difficult to judge the accuracy of the simulation results.

- There is no systematic procedure, and engineering skills and fluid dynamics knowledge are required.

- It is difficult to decide why/where it is needed and how to apply it.

- When using commercial programs, the software license fees are very high.

CFD analysis method

- Finite Volume Method (FVM): This is the method used by most CFD codes.

- Finite Difference Method (FDM): Used in the early days, but rarely used now.

- Finite Element Method (FEM): Mainly used for structural analysis rather than fluid analysis.

- Smoothed Particle Hydrodynamics (SPH): This method expresses a fluid as a collection of particles and tracks the movement of each particle, but its application is limited.

- Meshless CFD: Calculations are performed using a point distribution without a volume mesh. This eliminates the need for a mesh generation process and makes it very easy to simulate the motion of complex objects. Details on the meshless program (FAMUS)

CFD analysis procedure

The CFD analysis process consists of pre-processing – solving – post-processing.

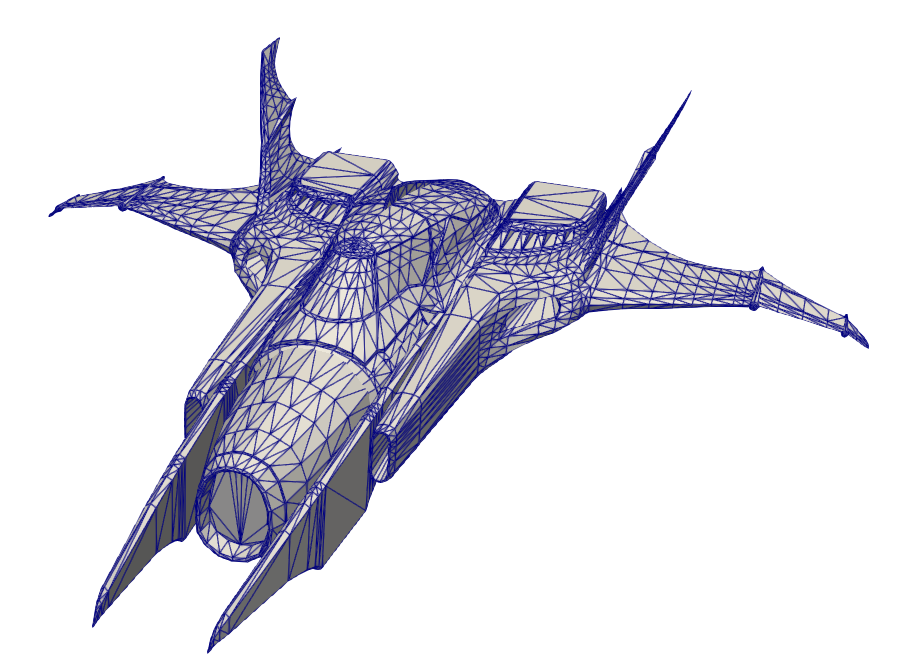

The pre-processing process involves preparing the geometry, generating mesh, and setting calculation conditions. Most geometry creation is done using 3D CAD programs. Spatial information data can be used to analyze wind conditions in urban or mountainous terrain, while 3D graphic data can be used for simple geometries. When generating mesh, the topology, cell size, and density are designed to match the problem, and mesh generation program is used.

Once the mesh is prepared, boundary conditions, initial conditions, physical models, numerical analysis techniques, etc. are set and calculations are performed using SMP, Cluster, Cloud, etc.

After the calculation is completed, post-processing steps such as extracting necessary data, creating images, creating videos, creating graphs, and writing reports are performed.

Advantages of CFD

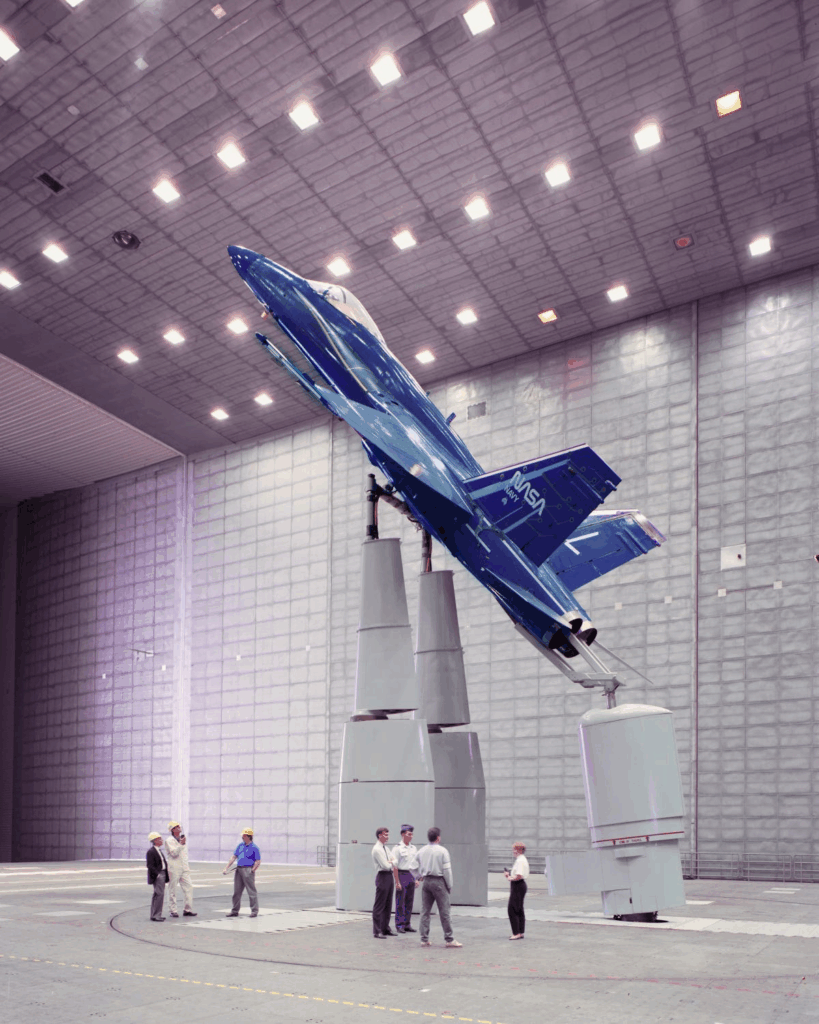

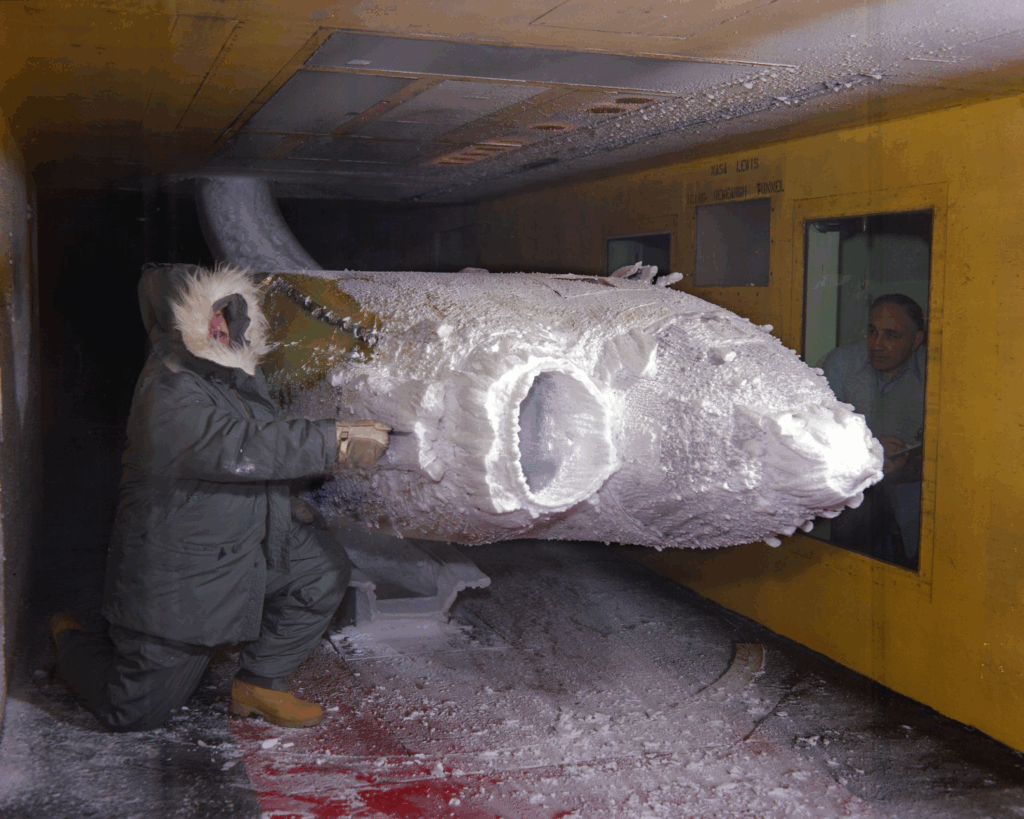

- Low cost: While generally considered cheaper than wind tunnel testing or model testing, this isn’t always the case depending on the modeling method and code used. However, in cases like the supersonic wind tunnel for a full-scale aircraft (shown below on the left) or the ice tunnel (shown below on the right), the cost difference can be significant.

- Speed: Results can be obtained quickly for a variety of conditions compared to wind tunnel testing or model testing.

- Simulate Real/Ideal Conditions: It has the advantage of being able to simulate extreme conditions that are difficult to implement experimentally, and of being able to implement ideal conditions that do not exist in reality.

- Comprehensive information: It is possible to obtain various physical information that is difficult to obtain through experiments.

- Users : While experiment needs test facilities and experts, everyone can do CFD simulation if use open source code.

CFD analysis program

- Open source code: available to anyone, with no limits on the number of users or parallel processing.

- Self-developed in-house code: Some universities, etc. write and use their own code.

- Commercial software: High licensing costs are a problem – limited number of users and parallel processing.

- CFD SaaS (Software as a Service): Available through cloud access, hardware usage fees are paid, and commercial software also requires licensing fees.

- Dedicated Program: A proprietary program developed in-house, based on open source, automating the analysis process. Developed to enable even non-CFD experts to obtain accurate results. Learn more.

The Past, Present, and Future of CFD

- ~late 1990s

- A small number of experts create and use codes themselves (ih-house code)

- Limited computing power → Applicable to 2D or very simple 3D problems for elucidating physical phenomena

- From 2000 to present

- Expansion of CFD utilization with the development of commercial software and HPC technology.

- Precise modeling using CAD, large-scale computation using clusters → simulation of real-world phenomena

- Combination with various physical phenomena (structure, chemical reactions, particles, noise, etc.), expansion into various fields

- The need for change

- High barriers to entry, expert-centric operations, increasing demand for interpretation, accelerating digital transformation, and increasing need for integration with other technologies.

- CFD democratization: Technological and environmental changes that make CFD analysis, previously expensive and technology-dependent, affordable and accessible to everyone (ensuring accuracy of results is a prerequisite).

- future

- The proliferation of open source programs

- Expanding user base through DIY (user-specific) CFD

- CFD code development, workflow optimization, minimal user experience, customized CAD

- Expanding data-driven simulations

- Convergence of AI and CFD