BARAM Release v25.3

Introducing the upgrades in BARAM-v25.3.

Data-driven real time simulator

Fan performance curve input method change

New material properties setting method

Add suffix option for project name

CFD code update – NextFOAM

NextFOAM code has enhanced certain dynamic mesh capabilities, and dynamic mesh functionality has been incorporated into the density-based compressible solver. In BARAM, the sliding mesh feature is now available for use within the density-based solver.

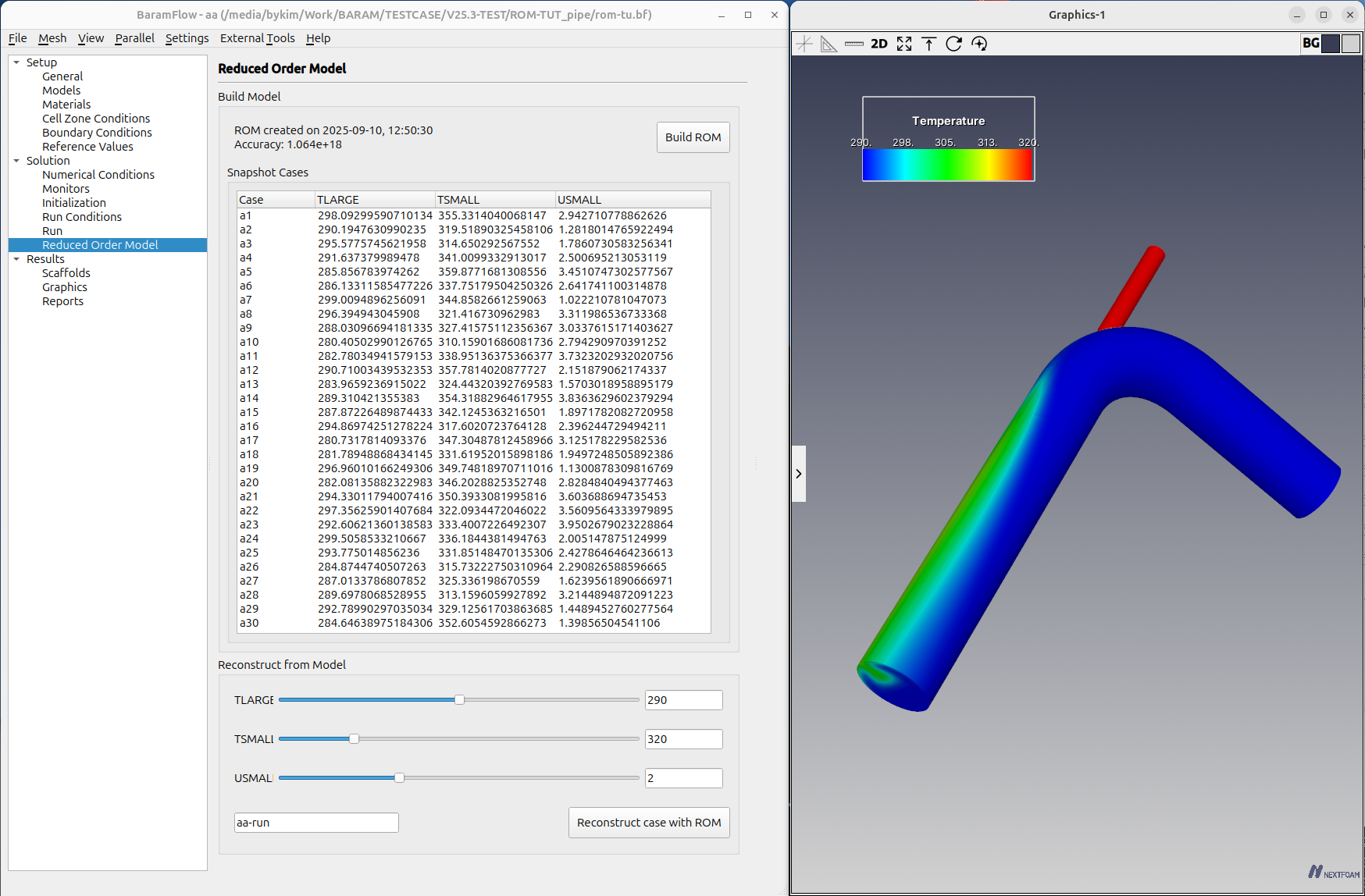

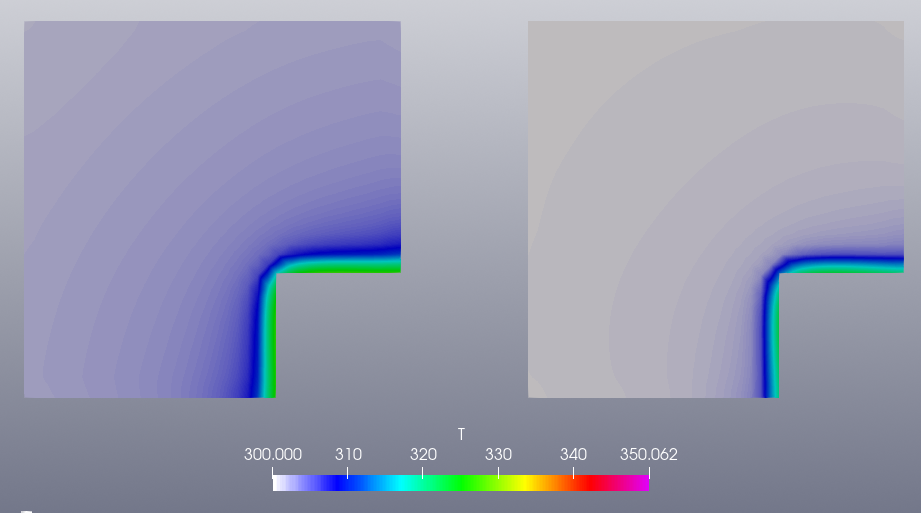

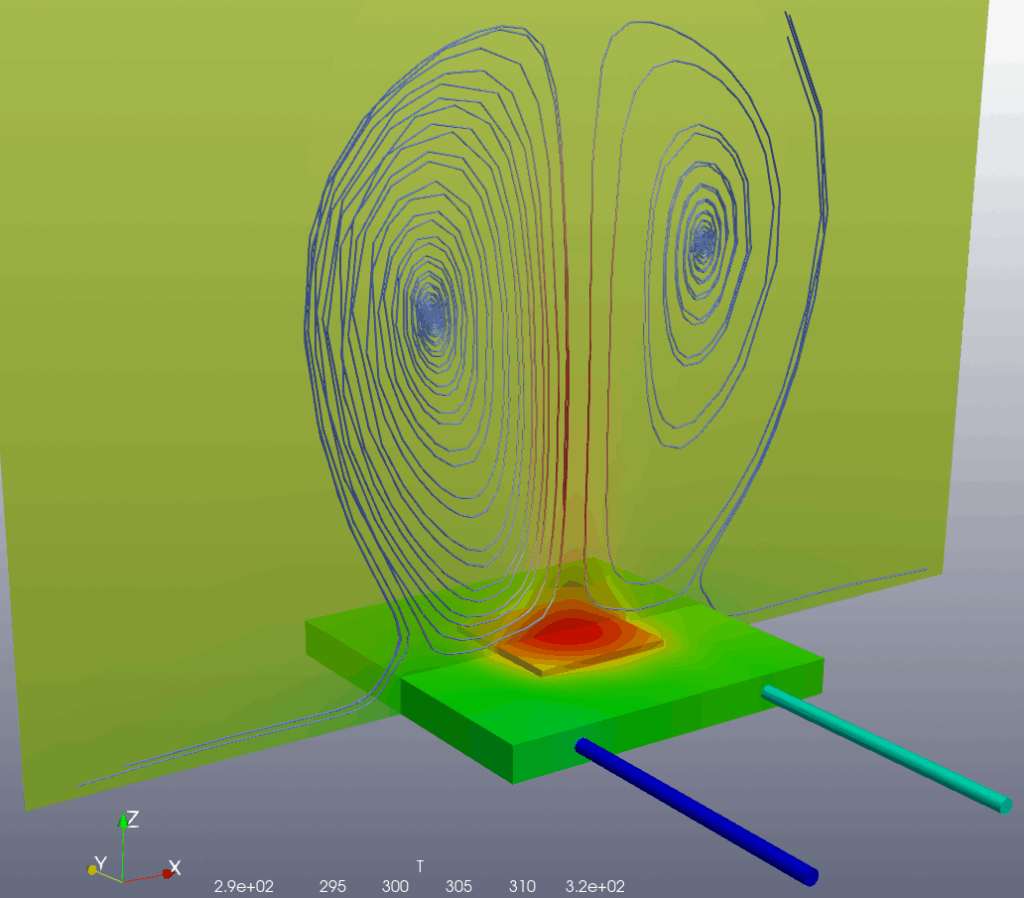

Data-driven Real Time Simulator

A data-driven real-time simulator creation feature has been added. Using results calculated for various conditions, you can obtain results for uncalculated conditions in real time. Using data created by BARAM’s batch run function as a snapshot, perform Proper Orthogonal Decomposition (POD) and create a Reduced Order Model (ROM). The generated data is added to the batch run results. It can be used as a thermal/fluid simulation engine within the digital twin workframe.

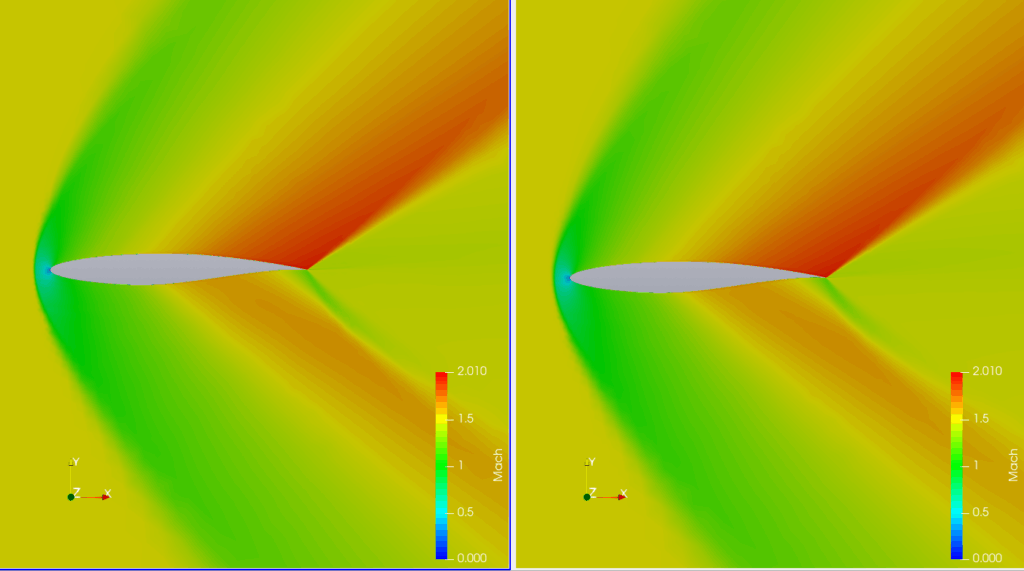

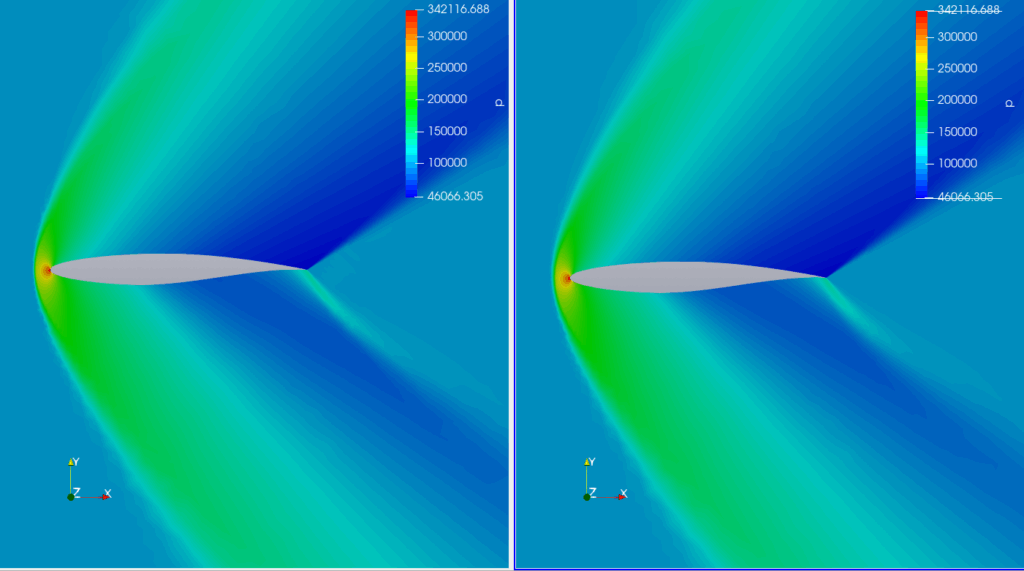

The figure below shows the predicted and calculated results for an angle of attack of 3 degrees in the batch run tutorial of angle of attack sweep (RAE2822 airfoil). The difference in drag is accurately predicted at 0.2%.

New Boundary Conditions

Flow rate outlet

Flow rate can now be defined at the outlet of the flow. Velocity uses a constant flow rate condition (flowRateInletVelocity), while pressure, temperature, turbulence, etc., use a zeroGradient condition.

Intake Fan/Exhaust Fan

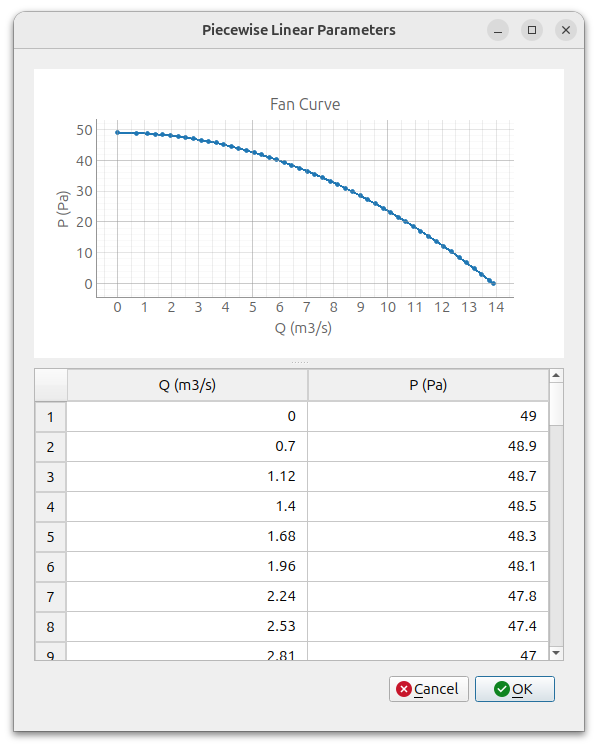

Fan conditions can now be applied to the inlet/outlet boundary surfaces of fluid flow. Use the fanPressure condition. Input the fan P-Q curve using a spreadsheet. You can copy and paste columns from spreadsheet programs like Excel.

One dimensional Thermal Conduction for baffle

When modeling a very thin solid within the calculation domain as a thicknessless baffle, the effect of thickness can be simulated through one-dimensional heat conduction calculations. The wall layers functionality used for external boundary surfaces has been applied to the baffle.

Fan performance curve input method Change

The method for inputting performance curves has been improved for both existing fan boundary conditions and the newly added intake fan and exhaust fan. It has changed from importing existing Excel or CSV files to copying and pasting data from spreadsheets.

New Material Properties setting method

Boussinesq approximation

In low-velocity flows with small temperature differences, such as natural convection problems, the Boussinesq approximation can be used, which expresses the density of the fluid as a function of temperature alone.

$\rho=\rho_0 [1 − \beta (T − T_0 )]$

Perfect fluid for liquid

The perfect fluid condition, which accounts for the compressibility of liquids, can be used. Density is calculated as a function of temperature and pressure using the reference temperature, reference density, and compressibility.

$\rho = \frac{p}{RT}$

$R=\frac{1}{\rho_0 \beta T_0}$

$\beta$ : compressibility

Janaf data for Cp

A method using NASA’s thermodynamic database Janaf has been added for calculating heat capacity (Cp). The issue where Cp could not be provided as a function of temperature when using perfect gas conditions has been resolved.

$\frac{Cp}{R}=a_1 + a_2 T + a_3 T^2 + a_4 T^3 + a_5 T^4$

$\frac{h}{RT}=a_1 + \frac{a_2}{2} T + \frac{a_3}{3} T^2 + \frac{a_4}{4} T^3 + \frac{a_5}{5} T^4 + \frac{a_6}{T}$

$\frac{s}{R}=a_1 ln T+ a_2 T + \frac{a_3}{2} T^2 + \frac{a_4}{3} T^3 + \frac{a_5}{4} T^4 + a_7$

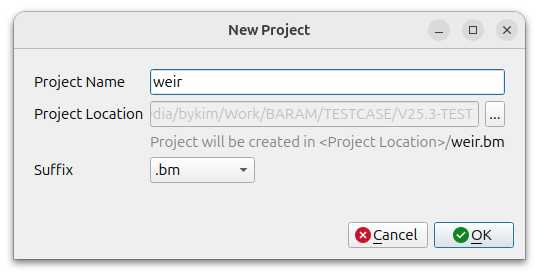

Add suffix option for project name

Since baram projects are managed as folders, it was sometimes confusing to distinguish between regular folders and baram project folders. Additionally, the lack of distinction between baramMesh and baramFlow folders was inconvenient. To address this issue, we added an option to use the .bf(for baramFlow) or .bm(for baramMesh) extension in the project folder name.

ETC

- When calculating force, we have changed from using absolute pressure to relative pressure. When calculating the force acting on the boundary surface, external forces are now calculated using the reference pressure, enabling the calculation of realistic forces. (Changed in Monitoring and Report)

- While the force coefficient is calculated using relative pressure, the force itself was being calculated using absolute pressure. When calculating forces acting on external walls, forces outside the computational domain must be subtracted. This required a large number of significant digits and posed challenges in accurately determining the area.

- An error causing occasional parallel computation failures in multi-region problems for specific core counts has been fixed. – Changed mappedWall’s polyPatchType from nearestPatchFaceAMI to nearestPatchFace

- Boundary surfaces are now sorted by name when copying.

- An error preventing the solid’s heat capacity (Cp) and thermal conductivity from being defined as polynomials has been fixed.

- An error causing graphic widgets to duplicate when saving a project under a different name has been fixed.