Development of a SaaS for simulating air pollution diffusion using CFD

Air pollution dispersion analysis is the process of studying how pollutants move and spread in the atmosphere, and plays a vital role in many fields, including air quality improvement, public health, public policy, and urban planning.

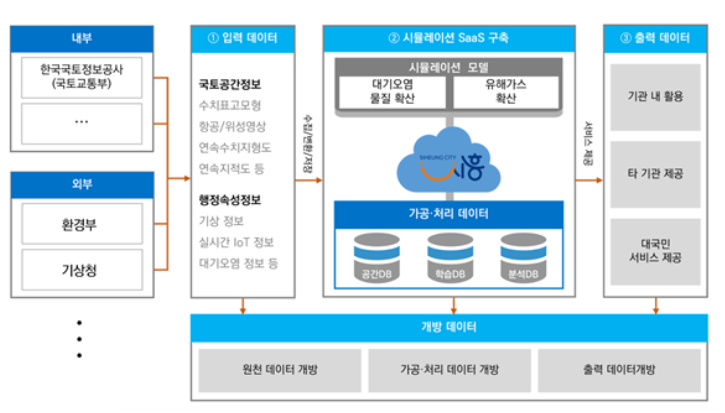

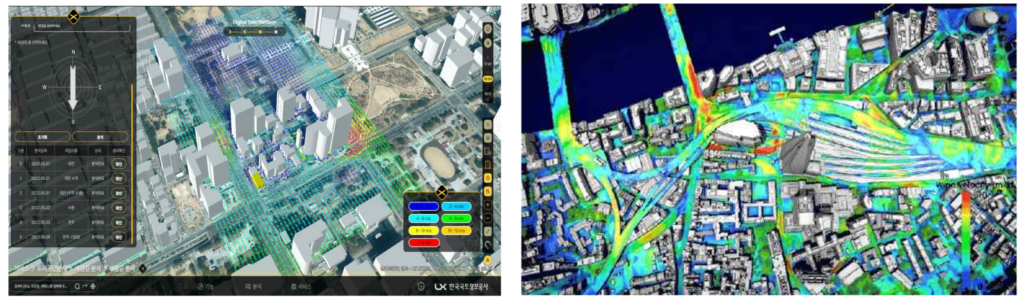

Computational Fluid Dynamics (CFD) techniques were used to accurately analyze air pollution diffusion. The analysis environment was implemented as a SaaS service on the public (Korea Land and Geospatial Informatix Corporation) digital twin platform, maximizing usability and accessibility. Sensor measurement data and simulation data were integrated.

Development scope

- Automatic generation of CAD data for the target area’s terrain, buildings, and wind resistance elements near the ground surface

- By linking weather information, actual weather information is reflected in simulations, improving the accuracy and reliability of results.

- Building a SaaS that enables simulation without specialized knowledge by automatically generating grids and performing simulations.

- Development of a cloud infrastructure design for driving a rendering engine that visualizes 3D simulation results.

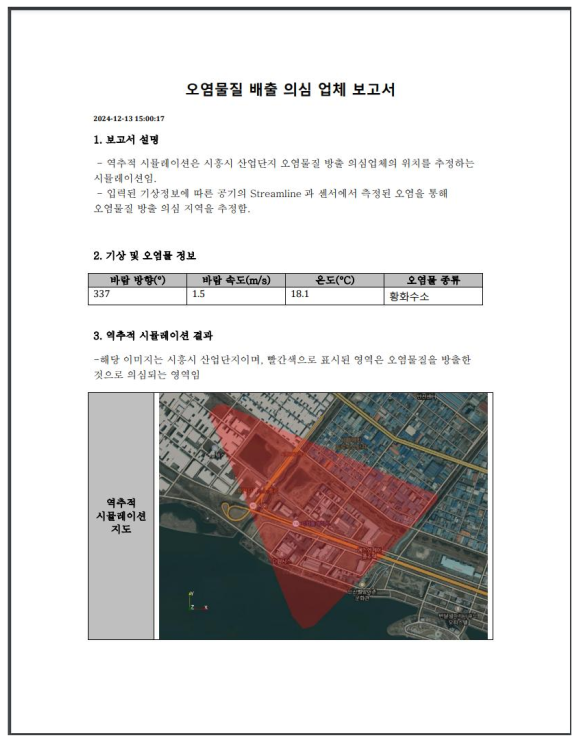

The target site is part of the Sihwa National Industrial Complex (approximately 22.627 km2) in Siheung-si, Gyeonggi-do, an area that is very vulnerable to environmental issues such as air pollution.

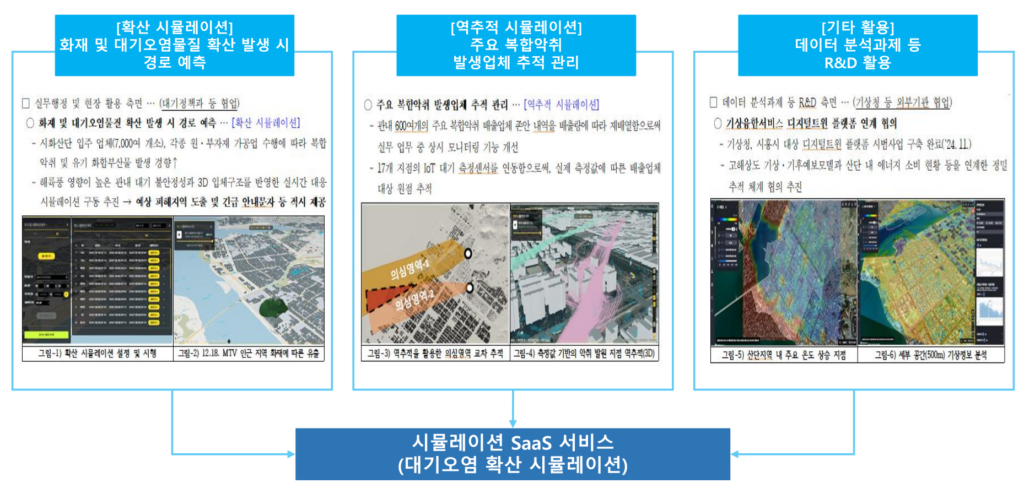

Utilization plan

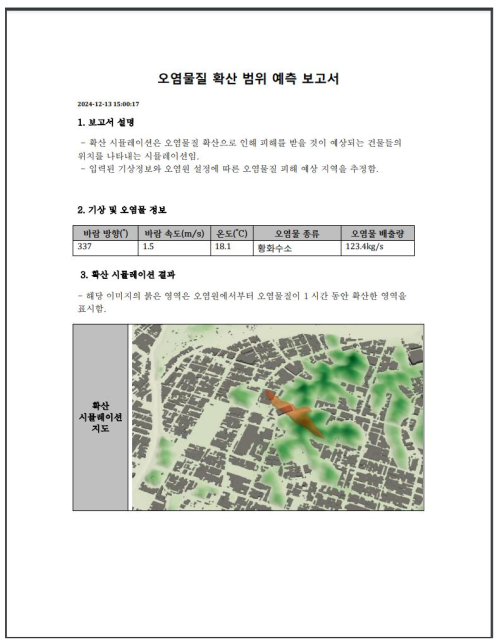

- Predicting the path of fire and air pollutant spread through diffusion simulation, deriving expected damage areas and providing emergency guidance text messages in a timely manner.

- Tracking and managing major complex odor generating companies based on actual measurement values by linking backtracking simulation and IoT atmospheric measurement sensors.

- R&D utilization such as data analysis tasks

Computational Fluid Dynamics Simulation Methods

Simulation software

The computational fluid dynamics program uses OpenFOAM, a leading open-source code. Open-source code requires no separate licensing fees, has no limitations on parallel computing, and facilitates development and modification for new features, making it ideal for public service platforms.

The following features were developed and added to the publicly available OpenFOAM code.

- Atmospheric boundary layer boundary conditions considering atmospheric stability – Implementing six Pasquill classes ranging from very unstable to stable.

- Contaminant diffusion simulation function

- Simulation function to trace the location of pollutant generation from sensor data

- Added solver stabilization device

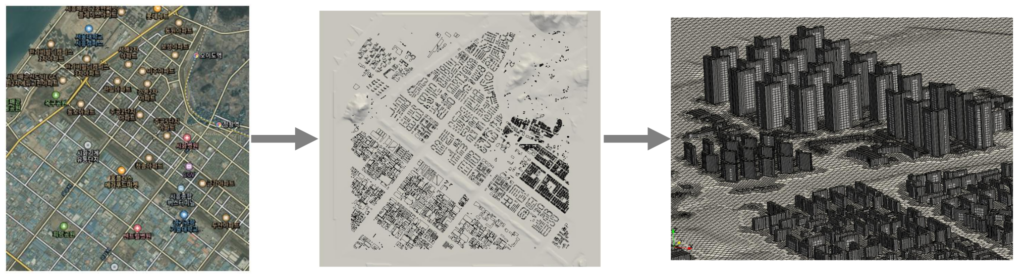

Automatic creation of shapes and grids using spatial data

We utilize data on the terrain, buildings, and wind resistance factors near the ground surface of the target site, built on the 3D spatial information platform of the Korea Land and Geospatial Informatix Corporation. To achieve this, we developed an interface module between the spatial data format used on the platform and the data format used in the simulator.

The topographic data from the digital topographic map is converted to an .obj file, and the building data is used to create the 3D shape of the building. This is then used to create a 3D grid using snappyHexMesh, OpenFOAM’s grid generation utility. This process is automated using an automated script based on input conditions, without user intervention.

Simulation

Once actual wind speed, direction, and temperature are provided through weather data linkage, the files necessary for calculations are generated and simulations begin in the cloud. Based on the calculated data, pollutant sensor data is input, and a backtracking simulation is run to estimate the location of the odor.

Post-processing automation

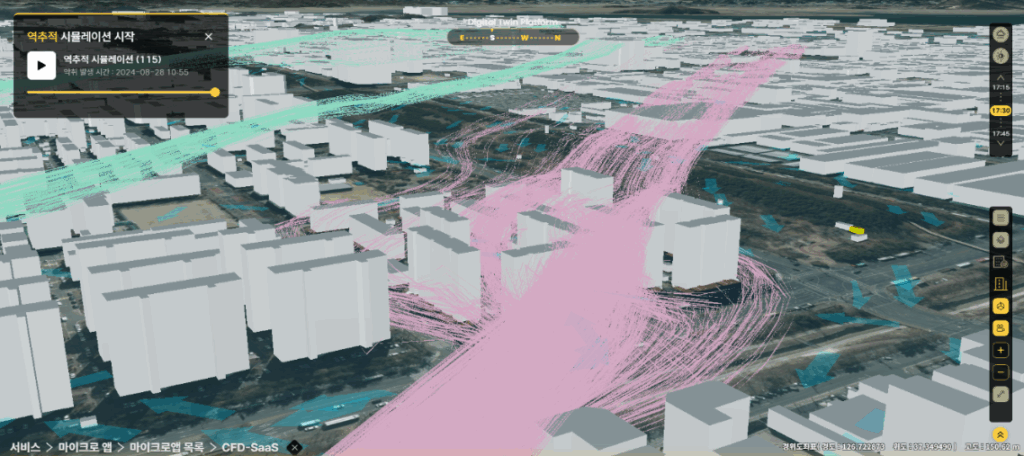

OpenFOAM calculation results are automatically generated using scripts in ParaView, a 3D data processing program, and converted into 3D visualization data in middleware to be visualized on a digital twin platform.

It automatically generates a report analyzing the extent of contamination spread based on the type and location of the source, and is used to predict areas likely to be affected by the spread of contaminants and take appropriate measures. A traceback report is used to create a list of companies suspected of emitting pollutants when sensors detect contamination.

Real-time simulator implementation

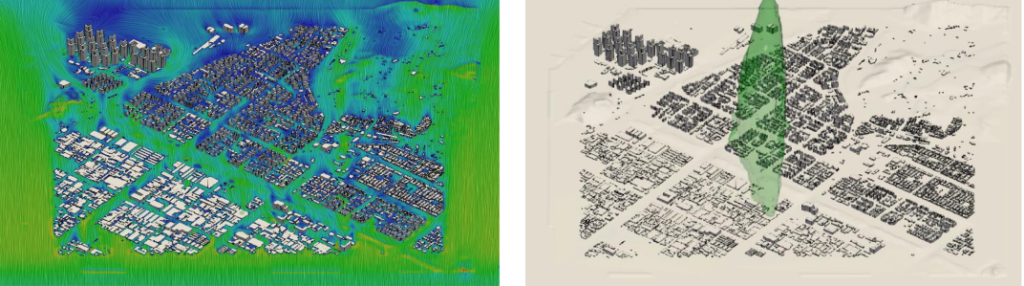

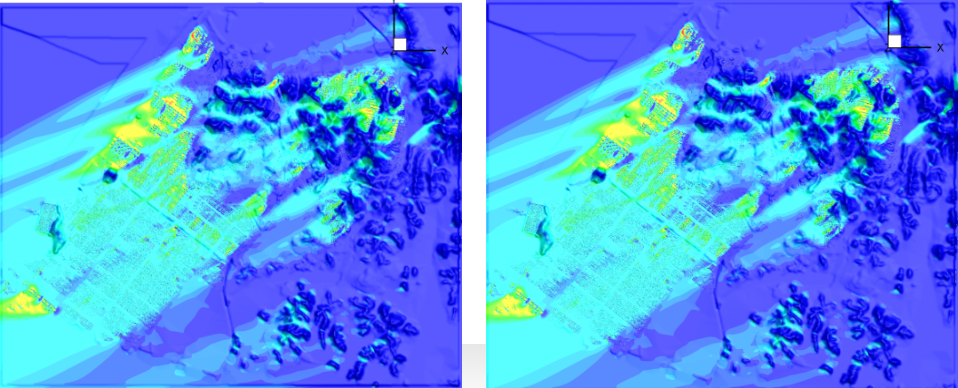

Because computational fluid dynamics (CFD) is computationally time-consuming, a reduced-order model is developed to obtain real-time data using simulation data for various conditions. Experimental points are derived from a given range of wind directions and speeds, and a database is built through simulations for each. Using the constructed analysis data, principal component analysis is performed using the Proper Orthogonal Decomposition (POD) technique, and a reduced-order model is created through artificial neural network learning. The generated model generates three-dimensional spatial results within seconds, with nearly the same accuracy as CFD simulations for uncalculated conditions. Therefore, simulation results can be obtained in real time simply by entering the conditions. The left side of the figure below shows the CFD results, and the right side shows the reconstructed results from the reduced-order model.

To analyze the spread of air pollution, we combined CFD, digital twins, and SaaS, built a public platform, and verified its performance.

Implementing CFD in digital twins requires automation of the entire preprocessing/calculation/postprocessing process, as well as the development of a real-time simulator utilizing a database. To achieve this, the use of open-source code that facilitates code development and automation, integrates easily with various programs, and is license-free is considered essential.